What is a Portal Axle? How Custom Drive Axles Solve Extreme Cold Construction Challenges

Technical Origins – What is a Portal Axle?

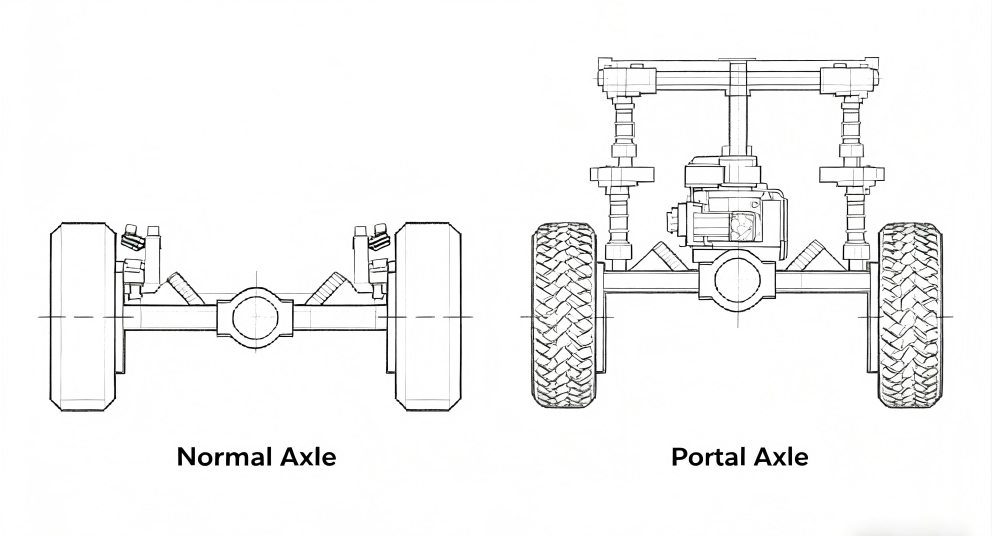

In the eyes of off-road enthusiasts and construction machinery engineers, the portal axle is a name synonymous with traversability and reliability. It is a special off-road vehicle suspension and drive technology. Its core design lies in this: the centerline of the axle's half-shaft or axle tube does not directly align with the wheel center, but is located above it. The driving force requires an additional gear set (the "portal gears" or "wheel hub reducer") installed on each hub to be transmitted to the wheels. You can imagine it as building a miniature "gear elevator" inside the wheel. This system brings two revolutionary advantages:

Revolutionary Ground Clearance Increase: Because the entire main reducer, differential, and main axle housing body are raised due to the elevated drive path, the vehicle's most vulnerable underbody areas—especially beneath the bulky main reducer housing—gain unprecedented ground clearance. This allows the vehicle to easily overcome rocks, stumps, or deep ruts that would pose a threat to standard axles.

Drivetrain Load Optimization: The hub gears provide secondary speed reduction and torque multiplication while transmitting power. This means the torque that the main reducer and half-shafts need to transmit is reduced before reaching the wheels. This not only allows for a lighter, more compact main reducer design (further aiding ground clearance) but also significantly reduces the load on upstream components like the propeller shaft and transfer case, enhancing the reliability and lifespan of the entire drivetrain.

This design is not new; its technical origins can be traced back to the German Volkswagen Type 82 military vehicle from WWII, which used a 1.4:1 portal gear ratio to effectively increase chassis height and achieve very low off-road crawling speeds. Today, portal axles are not only used in top-tier off-road vehicles and agricultural machinery but also appear in an "inverted" form in low-floor buses to reduce cabin floor height for easier passenger access. In the field of special engineering machinery, this classic design is gaining new vitality, with its value being fully realized especially on equipment demanding extreme traversability.

Advantages and Challenges – The Technical Dialectics of Portal Axles

Like any engineering technology, portal axles bring significant advantages alongside challenges that engineers must balance and overcome. Their exceptional strengths make them the preferred choice for extreme operating conditions.

Unparalleled Traversability: This is the most notable feature of portal axles. High traversability enables construction equipment to access work areas unreachable by standard equipment, making them particularly suitable for engineering machinery applications.

Optimized Drive Chain: The distributed torque transmission improves the working environment for the entire drivetrain, reduces potential failure points, and enhances durability. For engineering machinery requiring long-term continuous operation, this characteristic translates to higher availability and lower maintenance costs.

Potential for Low-Speed Control: Through appropriate gear ratio settings, extremely low and stable travel speeds can be easily achieved, which is crucial for engineering machinery requiring precise operation. On slopes or complex work surfaces, this precise speed control capability can often determine the success or failure of a project.

However, the challenges are equally clear:

Increased Unsprung Mass: Heavier, more complex hub components increase the wheel's "unsprung mass," which can somewhat impact ride comfort and handling precision at high speeds. This requires engineers to make more refined considerations in material selection and structural design.

Thermal Management Challenges: Under continuous, high-intensity operation, the compact hub gearbox can generate significant heat, placing higher demands on the design of the thermal management system.

Cost and Complexity: More complex structures inevitably lead to higher manufacturing costs and maintenance technical requirements. This also explains why portal axles are typically only used on special vehicles with specific traversability requirements.

Precisely because of this, the application of portal axles is a precise trade-off. They are not suitable for all vehicles but are specifically designed for scenarios where traversability and reliability are prioritized. This precise positioning gives portal axles irreplaceable value in specific engineering applications.

The Solution: Breaking the Ice – High-End Custom Grader Axles for the Russian Market

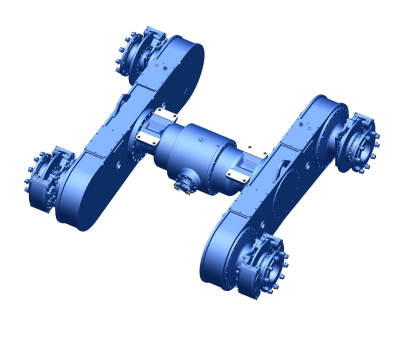

With a deep understanding of the technical essence and applicable boundaries of portal axles, we have successfully developed a fully-driven, fully-powered, highly customized drive axle solution tailored for harsh construction environments common in Russia, Belarus, and similar countries—such as soft snow fields half a meter deep, muddy swamp areas, undulating steep slopes, and demanding mine road maintenance tasks.

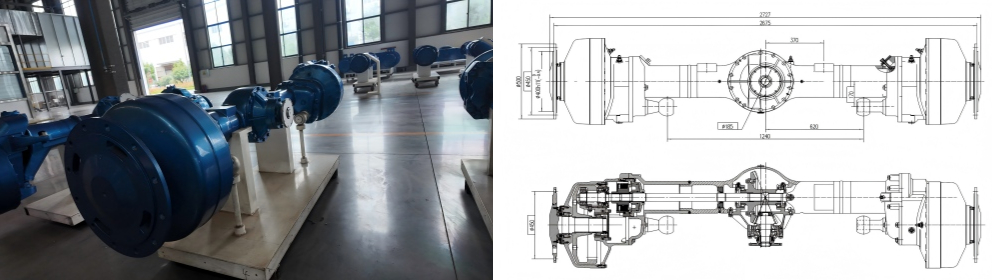

Triple-Drive Axles: Unafraid of Soft Ground and Steep Slopes. Unlike conventional graders, the triple-drive axle assembly we provide innovatively sets the front, middle, and rear axles all as grader axles. This means the engine's powerful torque can be efficiently distributed to all wheels, fully converted into the machine's robust traction. When facing the loose soil or steep slopes common in Russia, this configuration fundamentally changes the dilemma of traditional graders being prone to slipping and getting stuck. Every wheel is a driving wheel, working in synergy to provide unparalleled grip and climbing ability, significantly improving construction stability and operational efficiency, with advantages being more pronounced especially on slopes.

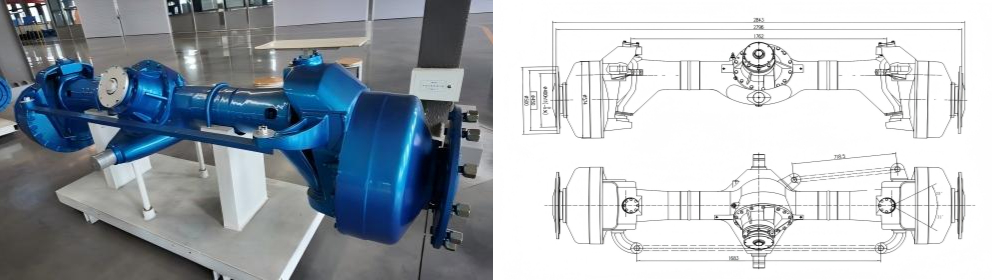

Front Axle Portal Structure, Combining Steering and Drive: The front steering drive axle is the embodiment of our technical strength—it adopts the classic and mature portal axle structure. There is a significantly calculated offset between its input shaft centerline and the wheel center. This design, while ensuring steering knuckle space and uninterrupted power transmission, provides a astonishing increase in ground clearance for the entire machine. It allows the grader to easily avoid obstacles with its key underbody components when crossing potholes, crushed stones, or driving on unleveled wilderness, effectively preventing damage and downtime caused by impacts. Simultaneously, the front axle transmits power via constant velocity double universal joint drive shafts, achieving high transmission efficiency; the steering system is assisted by hydraulics, ensuring light and precise steering operation even when completely stationary, and enabling stable steering without sideslip, balancing flexibility and reliability.

Co-Designed Middle and Rear Axles, Emphasizing Commonality and Adaptability: The middle and rear axle assemblies use consistent main structures, with only opposite input gear rotation directions. This highly serialized design philosophy stems from our deep consideration from the customer's perspective. It greatly enhances production and spare parts commonality, meaning customers only need to stock fewer part types to meet most maintenance needs, significantly reducing long-term maintenance costs and inventory pressure. For customers operating transnationally across the vast expanse of Russia, this convenience directly translates into improved operational efficiency. Additionally, the middle and rear axles are flexibly connected to the frame via an oscillating suspension, allowing them to better conform to the contours of uneven ground, ensuring more wheels maintain contact simultaneously, which enhances both traction and equipment travel stability. This system also considers maintenance convenience, reducing the disassembly/assembly time for key components by 40% compared to traditional designs, greatly improving equipment availability.

Customer Testimonial – Earning International Trust with Exceptional Quality

True technical value is proven in the crucible of the market. Our deeply customized grader axles have been supplied in batches for high-end graders in Russia, enduring the severe tests of several extreme cold winters and muddy springs locally. This product, specifically created for the Russian market, is a concentrated expression of our deep customization capabilities. The project initiation originated from specific requirements raised by the Russian client: they needed a grader drive solution that could maintain efficient operation under the extreme cold climate and complex terrain conditions of Siberia.

In the initial project phase, we formed a dedicated technical team composed of senior engineers, who made three trips to Russia for on-site inspections. Our engineers personally visited multiple construction sites, conducting in-depth exchanges with equipment operators, maintenance engineers, and project managers. Through this field research, we collected first-hand operational data and user needs, including the impact of low-temperature lubricant viscosity changes on starting performance and special traction requirements when traveling in deep snow.

Based on this valuable field data, we maintained close communication and collaboration with the client's technical team. This deep customization cooperation was reflected not only technically but also throughout the entire production process. We fully leveraged our company's flexible production advantages, opening a dedicated production line for this project while maintaining core process standardization. From raw material procurement to processing and assembly, special quality control points were established for each step, ensuring every drive axle assembly leaving the factory meets the usage requirements under extreme conditions.

A Equipment Director from a large Russian road construction company stated in feedback: "The permafrost and spring mud in Siberia used to be our biggest enemies for construction efficiency. Since introducing graders equipped with your portal drive axles, the situation has completely changed. Its triple-axle drive is immensely powerful; it has almost never gotten stuck on site. Particularly, the high ground clearance of the front axle gives us great confidence on rough, initially developed work sites. The reliability and durability of this grader axle assembly have exceeded our expectations and form the cornerstone of our long-term stable cooperation with your company."

Such evaluation confirms that our strategy of deeply integrating the classic portal axle technology with modern engineering machinery needs is correct. We are not just providing a grader axle; we are providing customers with a solution and the confidence to conquer extreme working conditions.

Future Outlook – Continuous Innovation, Driving Globally

As the global construction market demands increasingly stringent equipment efficiency, traversability, and reliability, the application prospects of portal axle technology in the field of special engineering machinery will broaden. Looking ahead, our company will continue to deepen its expertise in portal drive axle technology.

We will always be customer-demand-oriented, driven by technological innovation, providing a continuous core driving force for global customers to conquer even more challenging construction environments. Through persistent technological innovation and a comprehensive service system, we are committed to becoming a leader in the global special engineering machinery drive axle field, allowing "Chinese innovation" to shine even more brightly on the world stage of engineering machinery.

- Previous : Load Haul Dump Drive Axle: The "Power Core" Ensuring Efficient and Safe Operation of LHDs What is a Mining LHD? In the world of underground mining, characterized by confined spaces, harsh environments, and continuous operation, equipment faces extremely

- Next : What is the Service Life of a Drive Axle? Shandong Lutong Has the Answer