[New Product Release] High-end Backhoe Loader Drive Axles Make a Stunning Debut, Helping to Upgrade Engineering Efficiency

In recent years, global demand for multifunctional equipment in the construction industry has continued to rise. Backhoe loaders, leveraging their core advantage of "multi-tasking in one machine," have seen their market penetration grow year by year. In applications such as municipal emergency repairs, rural road construction, and large-scale agricultural planting, backhoe loaders can quickly excavate and efficiently load materials, increasing their single-machine operating efficiency by over 30% compared to traditional equipment. They have become standard equipment for small and medium-sized projects. As the core component that carries the weight and transmits power, the drive axle's performance directly determines the equipment's reliability and precision in complex working conditions, making it the "power center" of the backhoe loader.

Deeply Cultivating the Market, Mid-End Drive Axles Lay a Solid Foundation

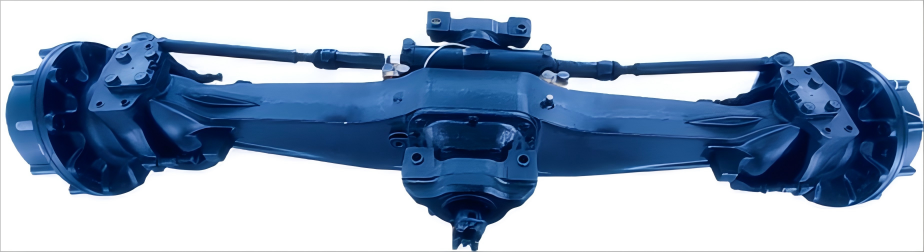

As a leading player in the drive axle field for construction machinery, our company has long developed a drive axle suitable for backhoe loaders—a 13-ton steering axle. This product focuses on the practical needs of small and medium-sized projects, designed with "stability, durability, and cost control" as its core concept, achieving a balance between price and performance. Its core advantages are:

1. The main drive unit utilizes Gleason involute bevel gears, offering high transmission efficiency and low noise.

2. The wheel hub utilizes an NGW-type planetary gear structure, offering a compact and sophisticated design.

3. The caliper-disc brake provides high braking torque, stability, and reliability.

4. The hydraulic steering system provides flexible operation.

5. The axle housing is constructed entirely of cast steel, offering strong load-bearing capacity and excellent rigidity.

6. It is suitable for 13-ton wheeled excavators or 10-12-ton backhoe loaders.

This drive axle has passed rigorous testing at national laboratories and, after mass production, has demonstrated stable operation and reliable quality, capable of meeting various complex operating conditions.

Technological breakthroughs: High-end drive axles reshape performance ceilings.

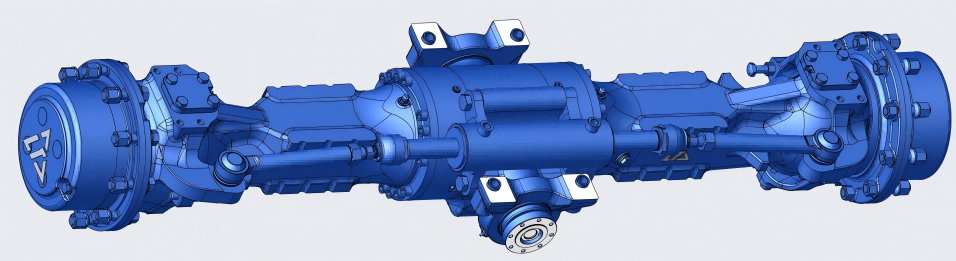

With the increasing number of complex operating conditions such as large-scale mining and high-altitude infrastructure projects, the market is placing higher demands on drive axles for load-bearing capacity, braking safety, and terrain adaptability. Based on years of technological expertise, our company has launched a new high-end drive axle for backhoe loaders. This series of front and rear drive axles features numerous technological innovations, achieving significantly improved performance.

The advantages of the front axle are:

1. A two-stage reduction system provides multiple speed ratios to meet the needs of various machine models.

2. A one-piece cast axle housing provides strong load-bearing capacity and excellent rigidity.

3. A swing arm connection to the vehicle lowers the vehicle's center of gravity and improves safety.

The advantages of the rear axle are:

1. A wet braking system is used. Traditional dry braking relies on air cooling, which can easily cause brake pads to thermally fade during continuous downhill braking or heavy loads. The new product utilizes a fully enclosed wet braking structure, immersing the brake pads in a specialized cooling fluid. This fluid circulates to remove heat, keeping brake temperatures low during continuous braking. Braking efficiency remains above 90% after 50 consecutive braking cycles.

2. A limited-slip differential is used. For low-grip surfaces like mud, ice, and snow, the new model features a multi-plate clutch-type limited-slip differential. When a significant speed difference occurs or one wheel slips, it automatically distributes power to the wheel with better grip, preventing operational interruptions caused by wheel slip.

3. Equipped with a differential lock, the driver can activate it with a single button in the cab, creating a rigid connection between the left and right axles. In extreme situations where one wheel is suspended in the air, it ensures 100% power transfer to the other wheel, helping the machine escape from a difficult situation. Locking response time is just 0.3 seconds, and upon unlocking, the differential automatically resumes function without affecting normal steering.

4. The integrated swing frame design effectively reduces bumps on uneven roads and enhances driver comfort.

5. The modular design allows for flexible adjustment of mounting distances, enabling more efficient and rapid vehicle matching.

Dual product lines running parallel, customized solutions covering all scenarios

The launch of this high-end drive axle for backhoe loaders complements the existing mid-range products, building a comprehensive product portfolio that caters to all scenarios. The mid-range series focuses on the cost-sensitive market, meeting the needs of routine operations on plains and hardened roads, offering a competitive price point compared to higher-end products. The high-end series targets large-scale projects and complex terrain, providing customers with solutions that offer "high performance and low lifecycle costs."

Both products can be customized to meet OEM requirements, matching engines, transmissions, and other chassis and drive components of varying power ratings. Our company will leverage technological innovation to continuously inject new momentum into the global construction machinery industry.