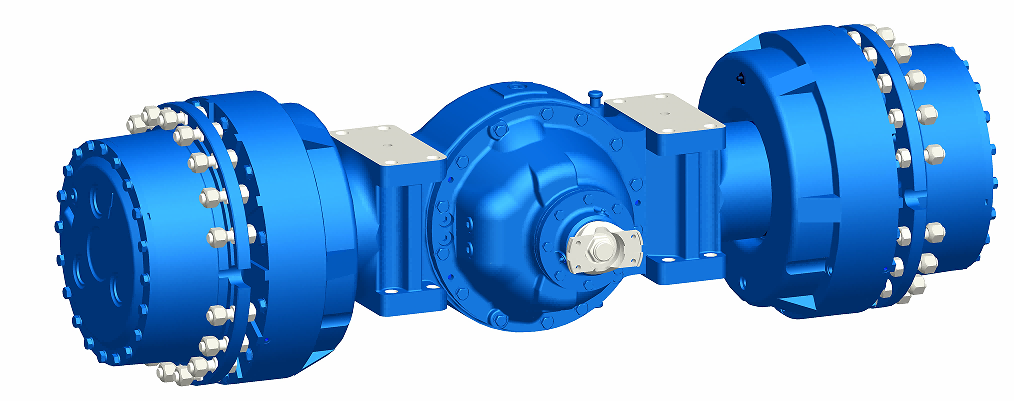

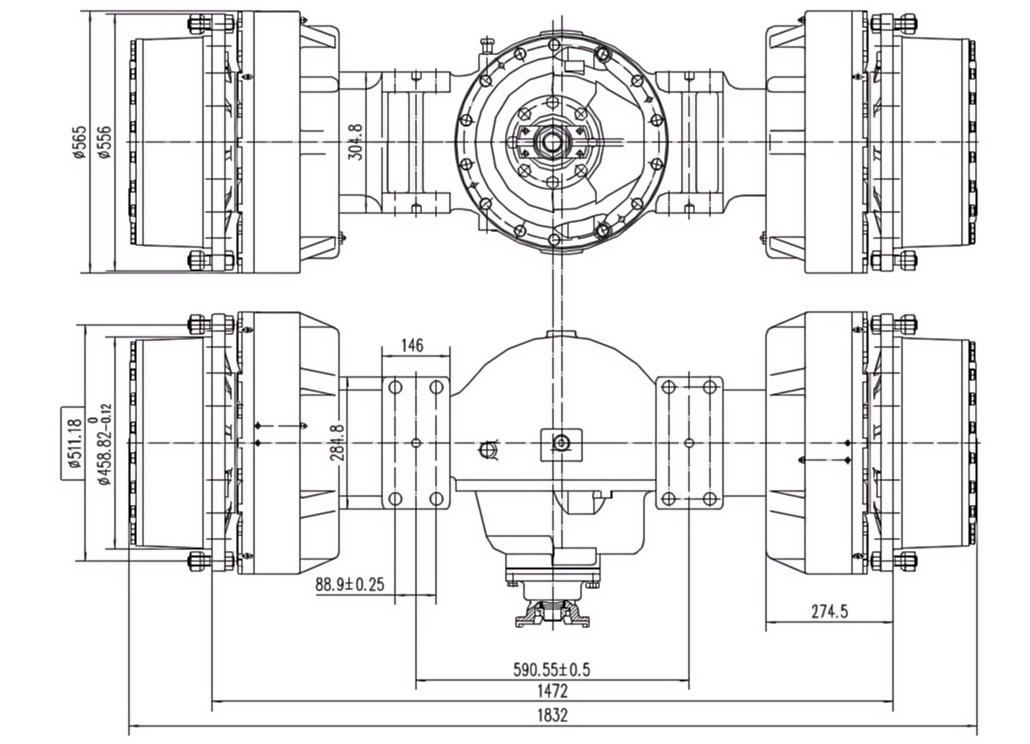

Axle Of 3 Cubic Underground Scraper

1. Engineered with a No-Spin limited-slip differential (LSD), this system ensures 100% traction control on muddy surfaces by fully preventing wheel slippage.

2. The wheel-integrated wet disc brake system combines service braking and parking braking functions into a unified mechanism (POSI-STOP), delivering fail-safe operational security.

3. Floating oil seals at wheel ends are specifically optimized for prolonged performance in high-moisture and sludge-intensive environments, featuring enhanced sealing durability.

4. Critical components sourced from globally certified Tier-1 suppliers ensure extended lifecycle reliability aligned with industrial duty-cycle requirements.

5. Steel casting axle house, more reasonable for two grades reduction transmission, achieving optimal load distribution and torque transmission efficiency.

6. Suited for 3 cubic underground carry scrapers.

Introduction:

The underground scraper axle is engineered for 3-cubic-meter underground scrapers, constructed with a robust integral cast steel axle housing. Its front axle is equipped with a No-Spin limited-slip differential (LSD), while the wheel-end assemblies utilize a dual-action spring-applied/ hydraulic-released braking system (POSI-STOP) paired with floating oil seals. This design delivers optimized adaptability and heightened operational reliability, specifically engineered to withstand the demanding conditions of underground mining operations.

Main technical parameters:

Total transmission Ratio | 26.118 |

Maximum input torque | 4290N.m |

Theory maximum load | 19050Kg |

Brake structure | POSI-STOP Spring brake/hydraulic pine brake |

Starting oil pressure of stopping braking | 10.4MPa |

Single braking capacity | 163.9ml |

Single braking moment | 20000N.m |

Brake cooling oil and Remove the brake oil | L-HL46 hydraulic oil |

Oil request for driving axle (API standard) | GL-5:85W/90 Gear Oil (above -12℃) |