Shandong Lutong: The Untold Story of China's "Hidden Champion" in Construction Machinery and Its Global Aspirations

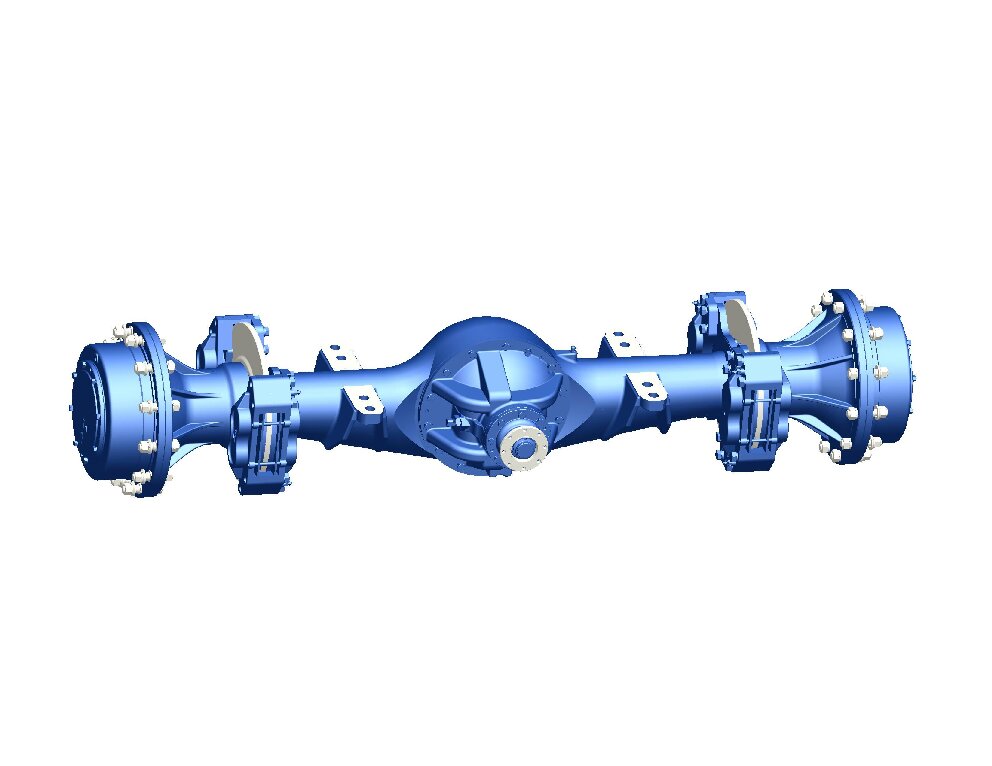

In the dynamic landscape of the global construction machinery industry, where precision, durability, and efficiency are paramount, the performance of drive axles stands as a critical determinant of an entire machine's operational prowess. These intricate components serve as the vital link between the engine's power output and the machine's ability to traverse challenging terrains, carry heavy loads, and execute complex tasks with precision. A subpar drive axle can lead to a cascade of issues, including diminished power transmission, increased fuel consumption, frequent breakdowns, and ultimately, a significant reduction in overall operating efficiency — factors that directly impact a construction company's bottom line and project timelines.

Against this backdrop, Shandong Lutong has emerged as a beacon of excellence in the realm of drive axle manufacturing. As one of China's preeminent professional producers of drive axles, the company has built a sterling reputation over the years, underpinned by its unwavering commitment to technological innovation, stringent quality control, and customer satisfaction. With a rich heritage of engineering expertise, Shandong Lutong has honed its craft to perfection, leveraging mature technologies that have been rigorously tested and refined in real-world operating conditions. This dedication to excellence has enabled the company to forge long-standing and mutually beneficial partnerships with some of the most renowned names in the construction machinery sector.

Among its esteemed clientele are industry giants such as SANY Heavy Industry, Liugong, Lonking, Xiamen Engineering Machinery (XGMA), Shantui, Develon, Lovol,and Breeton — names that are synonymous with quality and reliability in the global construction machinery market. By consistently delivering drive axles that meet and exceed the exacting standards of these leading original equipment manufacturers (OEMs), Shandong Lutong has solidified its position as a trusted supplier, playing an integral role in powering the machinery that builds nations and shapes landscapes.

|

A bold statement encapsulates the company's market presence: "3 out of every 10 loaders in China are equipped with our drive axles." This statistic is not just a numbers game; it is a powerful indicator of the trust that domestic manufacturers and end-users place in Shandong Lutong's products. It underscores the company's dominant position in the Chinese loader drive axle segment and speaks volumes about the reliability and performance of its offerings.

Unlike consumer brands that strive for household recognition, Shandong Lutong has chosen to let its products speak for themselves in the specialized domain of construction machinery. Within this industry, however, its name carries immense weight, serving as a byword for "reliable transmission." This hard-earned reputation has been forged through years of consistent performance, with each drive axle rolling off the production line embodying the company's commitment to excellence. As an esteemed supplier to industry leaders such as SANY Heavy Industry, Liugong, Lonking, Shantui, and Lovol, Shandong Lutong's loader drive axles have cemented their place in the market through a combination of cutting-edge technology, robust construction, and unwavering reliability — qualities that collectively constitute the "hardcore advantages" that set them apart from the competition.

At the heart of Shandong Lutong's product portfolio lies its range of high-performance loader drive axles, which represent the pinnacle of the company's engineering capabilities. These drive axles are the result of extensive research and development, drawing on the latest advancements in mechanical engineering and materials science to deliver unparalleled performance in demanding operating environments. Specifically designed to cater to the needs of 5-ton series loaders — workhorses of the construction industry that are tasked with a wide array of heavy-duty applications — these drive axles boast a host of technical advantages that make them the preferred choice of discerning OEMs and operators alike.

One of the key strengths of Shandong Lutong's loader drive axles is their efficient transmission structure, which has been meticulously engineered to maximize power transfer while minimizing energy loss. The adoption of a two-stage reduction design is a testament to the company's focus on optimizing transmission efficiency. At the heart of this design is the main reduction unit, which employs Gleason spiral bevel gears — a choice that is far from arbitrary. These gears are renowned in the industry for their superior meshing characteristics, which result in exceptionally high transmission efficiency. This means that a greater proportion of the engine's power is effectively transferred to the wheels, translating into enhanced machine performance and reduced fuel consumption.

Complementing the main reduction unit is the wheel-end NGW-type planetary reduction structure, which further enhances the drive axle's performance. This compact and ingeniously designed system offers a host of benefits, including a space-efficient layout that allows for easier integration into the loader's overall design. Despite its compact size, the NGW-type planetary reduction structure delivers impressive load-bearing capacity, enabling the loader to handle heavy loads with ease. This robustness makes it particularly well-suited for high-intensity operation requirements, such as those encountered in large-scale construction sites, mining operations, and material handling facilities.

Recognizing that different construction projects present varying challenges, Shandong Lutong has incorporated flexible differential options into its loader drive axles. This customer-centric approach ensures that the drive axles can be tailored to meet the specific needs of different working conditions. Operators can choose between a standard ordinary differential and a No-Spin limited-slip differential, each offering distinct advantages.

Safety is a paramount concern in any construction environment, and Shandong Lutong's loader drive axles are equipped with a reliable braking performance system that leaves no room for compromise. The adoption of a caliper disc brake system is a deliberate choice, driven by the need to ensure maximum stopping power and responsiveness. These brakes deliver a large braking torque, enabling the loader to come to a halt quickly and safely, even when carrying heavy loads or traveling at speed.

The rapid response time of the braking system is equally critical, as it allows operators to react swiftly to unexpected situations, minimizing the risk of accidents and ensuring the safety of personnel and equipment on the job site. In combination, these features guarantee that the loader can operate with the highest levels of safety and reliability, even in the most demanding circumstances.

Beyond the technical excellence of its products, Shandong Lutong places a strong emphasis on ensuring stable supply and maintaining the highest standards of quality — a commitment encapsulated in its guiding principle of "Stable supply, quality first." To achieve this, the company has invested heavily in state-of-the-art production and testing equipment, creating a manufacturing ecosystem that is designed to deliver consistent quality across every unit produced.

From the precision machining of components to the final assembly and testing of the drive axle, every step of the production process is subject to rigorous quality control measures. Advanced testing equipment is used to conduct a battery of checks, including performance testing, durability testing, and stress testing, to ensure that each drive axle meets the company's stringent specifications. This unwavering focus on quality not only ensures that customers receive products they can rely on but also helps to minimize the risk of costly downtime and repairs in the field.

While Shandong Lutong has earned its stripes as a leading manufacturer of drive axles for construction machinery, the company's expertise extends far beyond this core segment. Recognizing the interconnectedness of various heavy machinery sectors, Shandong Lutong has expanded its product portfolio to cater to the needs of mining machinery, agricultural machinery, and forestry machinery — industries that share similar demands for robust, reliable, and high-performance drive systems.

This diversification has not only broadened the company's market reach but also allowed it to leverage its engineering expertise across different domains, fostering cross-pollination of ideas and driving innovation. As a result, Shandong Lutong's products can be found powering a wide range of machinery, from massive mining trucks and excavators to agricultural tractors and forestry harvesters, further solidifying its position as a versatile and trusted supplier in the heavy machinery industry.

The company's products have become a staple in the offerings of well-known construction machinery brands such as SANY Heavy Industry, Liugong, Lonking, Shantui, and Lovol, a testament to the quality and reliability that Shandong Lutong consistently delivers. In the international arena, the company's star is also on the rise, with its products making significant inroads into markets around the world. Notably, Shandong Lutong's high-horsepower tractor drive axles and grader drive axles have been exported in substantial quantities to esteemed companies such as amkodor, PTZ, and UMG — names that carry significant weight in their respective markets. Perhaps most impressively, the company has achieved a remarkable feat in the Russian market: a zero accident rate with its products. This outstanding record is a powerful endorsement of the quality, reliability, and safety of Shandong Lutong's drive axles, earning the company the unanimous praise and trust of its international customers.

At the heart of Shandong Lutong's success lies its unwavering commitment to the principle of "Quality First, Customer Foremost." This philosophy permeates every aspect of the company's operations, from the procurement of raw materials to the final delivery of products to customers. The company exercises stringent control over the entire supply chain, carefully selecting suppliers who share its commitment to quality and subjecting all incoming raw materials to rigorous testing to ensure they meet the highest standards.

Shandong Lutong's journey of success is underpinned by a relentless focus on technical accumulation and market expansion. Over the years, the company has invested heavily in research and development, assembling a team of highly skilled engineers and technicians who are at the forefront of drive axle technology. This team is constantly exploring new materials, designs, and manufacturing processes, striving to push the boundaries of what is possible in drive axle performance.

The company's commitment to innovation is driven by a deep understanding of the evolving needs of its customers and the dynamic nature of the industries it serves. For example, in response to the growing global emphasis on sustainability and the rapid development of new energy technologies, Shandong Lutong has turned its attention to the new energy construction machinery market. Recognizing the unique requirements of electric loaders, which operate on battery power and demand high efficiency and low energy loss, the company has developed specialized drive axle solutions tailored to these machines. These solutions not only ensure optimal power transmission but also contribute to extending the battery life of electric loaders, making them more viable and efficient alternatives to their traditional counterparts.