Shandong Lutong drive axle--Precision inspection, quality and ingenuity to build a good drive axle

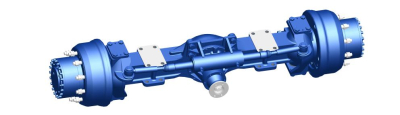

On the roaring mining operation surface, the drive axles of mining machinery carry heavy loads and continue to operate; in busy farmland, the drive axles of agricultural machinery drive agricultural tools for deep plowing and intensive cultivation; in logistics and warehousing parks, the drive axles of telescopic forks accurately drive the flexible transfer of equipment-the drive axles, as the “power heart” of construction machinery, agricultural machinery, and mining machinery, their quality is directly related to the operating efficiency, operating safety and service life of the whole machine.Shandong Lutong Heavy Industry Machinery Co., Ltd. has been deeply engaged in the field of drive axle manufacturing for many years, and has always engraved “quality is king” into its development genes, and has built a refined quality inspection system covering the whole production process.From the entry of raw materials into the factory to the delivery of finished products, every link is accurately controlled by strict standards, and professional testing and ingenuity are used to build a strong line of defense for the excellent quality of a full range of products such as loader drive axles, telescopic fork loading drive axles, and backhoe loader drive axles.

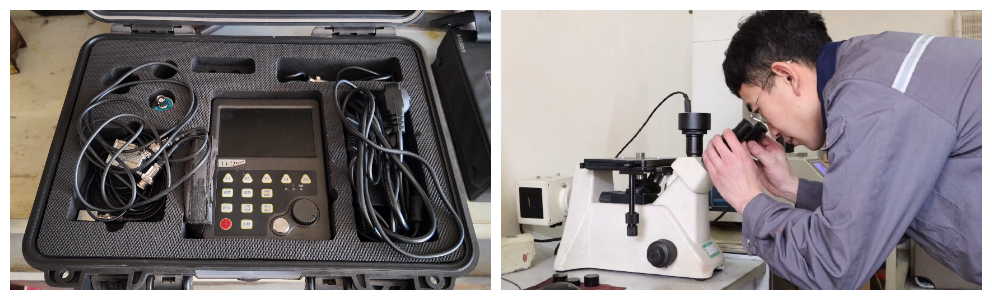

Raw materials are the “first threshold” of product quality, and Shandong Lutong Heavy Industry has almost stringent testing standards for this.When a batch of high-quality steel used to produce the drive axle housing of the backhoe loader arrived at the workshop, the inspection engineer immediately stepped forward with a spectrometer in his hand and accurately pointed the probe at the surface of the steel. The content data of various elements instantly jumped out on the screen.“Each batch of raw materials must undergo a comprehensive ‘physical examination’ by the spectrometer to ensure that the content of carbon, manganese, chromium and other elements fully meets the design requirements, and fundamentally guarantees the high strength and high toughness required for the drive axle.”The inspection engineer introduced while recording the data.

Entering the processing link, the quality of welding and the control of the inherent quality of parts are equally important.In the welding workshop, the blue welding flowers splashed, and the technical personnel strictly controlled the welding current, voltage and other parameters, while the ultrasonic inspection equipment was like a “golden eye”, followed by a full range of flaw detection of each weld, even micron-level cracks and pores are invisible, ensuring that the strength of the weld is perfectly matched with the base material.In addition to hardness testing, the technical team will also use a metallographic detector to delve into the inherent microscopic qualities of parts-this precision equipment is like a “magnifying glass of the microscopic world”, which can clearly present the grain morphology, distribution law and internal organizational structure of metal materials.Through the detection of the metallographic detector, the technical personnel can accurately determine whether the parts and materials have organizational defects, ensure that their internal structure is uniform and stable, and then ensure that the parts have the mechanical properties adapted to the heavy-duty and impact-resistant requirements of the drive axle, and build a solid foundation for the long-term stable operation of the drive axle from the internal structure level.The machining accuracy directly affects the assembly accuracy and transmission efficiency of the drive axle.Shandong Lutong Heavy Industry did not hesitate to introduce the world's top Hexagon three-coordinate testing equipment to perform micron-level measurements of key components such as the drive axle housing, gears, and half shafts with an accuracy of up to 0.001mm.Inspectors operate the equipment, the probe moves smoothly on the surface of the parts, and the dimensional data fed back in real time is accurate to every subtle corner; coupled with the surface finish testing instrument, carefully verify the smoothness of the surface of the parts to ensure that all parts can fit accurately, laying a solid foundation for subsequent assembly.

The machining accuracy directly affects the assembly accuracy and transmission efficiency of the drive axle.Shandong Lutong Heavy Industry did not hesitate to introduce the world's top Hexagon three-coordinate testing equipment to perform micron-level measurements of key components such as the drive axle housing, gears, and half shafts with an accuracy of up to 0.001mm.Inspectors operate the equipment, the probe moves smoothly on the surface of the parts, and the dimensional data fed back in real time is accurate to every subtle corner; coupled with the surface finish testing instrument, carefully verify the smoothness of the surface of the parts to ensure that all parts can fit accurately, laying a solid foundation for subsequent assembly.

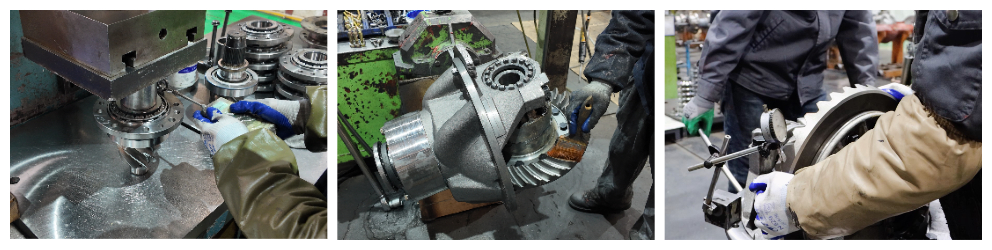

If accurate testing is the “guarantee line” of quality, then strict process procedures and quantitative management are the “stabilizer” of quality.In the core assembly process, technical personnel strictly follow the standardized operation process, hold a professional torque wrench to adjust the bearing preload, and keep their eyes on the instrument value to ensure smooth bearing operation and stable bearing; use high-precision tools to repeatedly calibrate the gear meshing area and the meshing gap to make the gear transmission smooth and efficient, minimizing noise and energy loss.“For products such as telescopic fork loader drive axles and backhoe loader drive axles that are often in heavy-duty and high-frequency operations, the precise control of this step directly determines the service life and operating stability of the equipment.”The assembly team leader said.

In the torque control link, high-precision torque testing equipment “stands guard” throughout the process, detecting each fastening bolt and transmission connector one by one, and feeding back data in real time to prevent damage caused by loosening or overload of components caused by insufficient torque.Before the finished product leaves the factory, a more stringent “ultimate test” is being staged: technical personnel place the drive axle on a test platform that simulates actual operating conditions, carry out long-term bench tests, and monitor key data such as speed, torque, and temperature rise throughout the process to ensure stable product performance under high-intensity operations; then conduct air tightness tests, closely monitor pressure changes through professional instruments, thoroughly investigate sealing hidden dangers, and eliminate leakage problems.Only by successfully passing these two key tests and confirming that there is no hidden danger of failure of the drive axle can we obtain a “qualification certificate” for shipment from the factory.

“Quality is the lifeline of an enterprise. The delivery of each drive axle carries our responsibility and commitment to our customers, and it is our core competitiveness based on the industry."The relevant person in charge of Shandong Lutong Heavy Industry spoke in a firm tone when talking about the concept of quality control.Since its inception, the company has always adhered to the craftsman spirit of “meticulous craftsmanship and excellence”, continuously invested in R&D resources to optimize the quality inspection system, and integrated international advanced testing technology and local process experience to make each drive axle both reliable and durable.Whether it is a mining machinery drive axle adapted to harsh mining environments, an agricultural machinery drive axle adapted to diverse farmland scenarios, or a telescopic fork loader drive axle and backhoe loader drive axle adapted to logistics and engineering fields, it can accurately match customer needs with excellent quality and provide safe and reliable transmission solutions for global partners, which has won wide recognition and praise.

From the strict selection of raw materials to the precise testing of the processing link, from the fine control of the assembly process to the rigorous testing before leaving the factory, Shandong Lu General's ingenuity in the whole process interprets the quality responsibility of China Heavy Industry Manufacturing.In the future, the company will continue to deepen the field of quality control, continue to introduce advanced testing technology and management concepts, continuously improve the core competitiveness of its products, and enable the development of the global construction machinery, agricultural machinery and mining machinery industries with higher-quality drive axle products, demonstrating the hard-core strength of China's intelligent manufacturing.