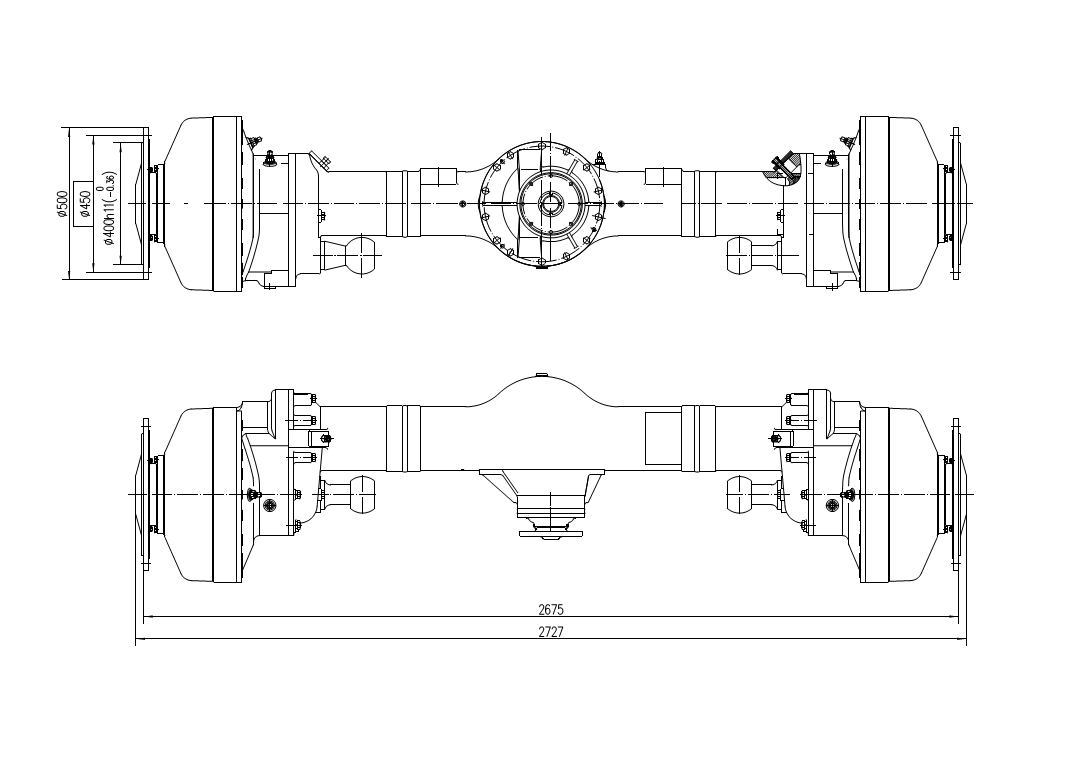

Drive Axle of Grader

1.Customizable compact modification solutions to meet specific needs

2.3D model pre-adaptation service provided during customization phase

3.Rapid replacement part delivery to minimize equipment downtime losses

4.Remote technical support available for worry-free operation

Introduction:

Drive Axle of Grader is designed to deliver powerful traction and rip-up force while ensuring high mobility on rugged terrain and reliable continuous operation. It is a mature product developed to meet the demanding requirements of grader applications.The drive axle features a classic portal axle design. Its core characteristic is the significant offset between the centerline of the input shaft and the wheel center. This design ensures efficient power transmission while substantially increasing the ground clearance of the entire axle, enabling the equipment to easily traverse complex working conditions such as potholes, gravel, and uneven surfaces. It effectively reduces the risk of undercarriage impacts and significantly enhances the machine’s overall mobility and off-road adaptability.The braking system utilizes multi-disc wet brakes mounted at the wheel ends. Multiple friction pairs are fully enclosed within a brake chamber filled with cooling oil. This design not only isolates external contaminants such as mud, water, and dust, greatly extending the service life of the braking components, but also provides a larger heat dissipation area and continuous cooling through the oil. This effectively suppresses heat buildup under severe conditions like continuous braking on long slopes, significantly reducing brake fade and ensuring consistent, linear braking force output for safe operation.

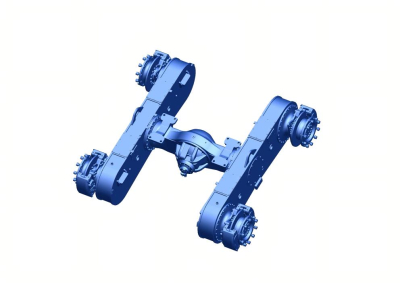

The drive axle can be installed as either a middle or rear axle on the grader. The middle and rear axle assemblies share the same structure, with only the rotation direction of the input gear being opposite. This modular design philosophy greatly improves parts commonality for production and spare parts, reduces maintenance costs, and provides significant convenience for international operations and after-sales service. Users worldwide can access efficient and unified technical support, ensuring high equipment availability and operational efficiency.The machine adopts a three-axle drive layout (with a front steering drive axle combined with this middle/rear axle). All three axles provide power, efficiently converting engine torque into strong traction for the entire machine. This power configuration enables the grader to demonstrate outstanding driving performance and anti-slip capability, even when facing soft soil, steep slopes, or extreme heavy-duty grading operations commonly encountered in regions such as Russia and Belarus. It significantly enhances construction stability and efficiency.This systematic drive solution, with its reliable quality and excellent environmental adaptability, has become a trusted choice for numerous international users. In addition to this product, our company also offers a variety of portal axles for sale to meet customized needs of different customers.

Main technical parameters:

Total transmission ratio | 17.357 |

Maximum input torque | 6100N.m |

Maximum input rotate speed | 3450r/min |

Rating load | 18800Kg |

Braking air pressure | 0.75MPa |

Brake structure | Wet multi-disc brake |

Oil request for driving axle (API standard) | GL - 5:80W/90 gear oil (above - 12°C) GL - 5:80W/90 gear oil (above - 26°C) |

Customer Cases

Since its launch for bulk export, this portal axle has maintained stable quality control, and to date, no feedback regarding quality complaints or performance issues has been received. Meanwhile, positive client evaluations continue to grow: cooperative customers have repeatedly mentioned in communication that "the product failure rate is significantly lower than the industry average" and "the attention to detail in craftsmanship exceeds expectations." Some long-term clients have explicitly expressed intentions to "expand procurement scale and deepen annual cooperation," confirming market recognition of the product quality through concrete actions.

Product Development Capability

Our company consistently focuses on customer needs, actively providing innovative solutions and emphasizing market expansion and product development. We are committed to meeting market demands by continuously launching highly competitive products and offering custom axles tailored to specific client requirements. To date, we hold dozens of national patents and are recognized as a National High-Tech Enterprise. We also maintain long-term collaborations with research institutions such as Shandong University, Jilin University, and Tianjin Engineering Machinery Research Institute, enhancing our R&D and production capabilities.

Our company boasts a strong product development team, fully functional product development laboratories, and physical & metallographic testing labs. Equipped with advanced machining tools, precision inspection instruments, comprehensive experimental facilities, sophisticated manufacturing processes, and testing methods, we are dedicated to technological innovation, continuous improvement, lean production, and sound management to deliver excellent products and full-range services. Ample spare parts inventory and a robust service system ensure efficient and high-quality after-sales support, fully meeting customer needs for training, service, and parts.